Hendersonville’s Premier Industrial Refinishing Shop

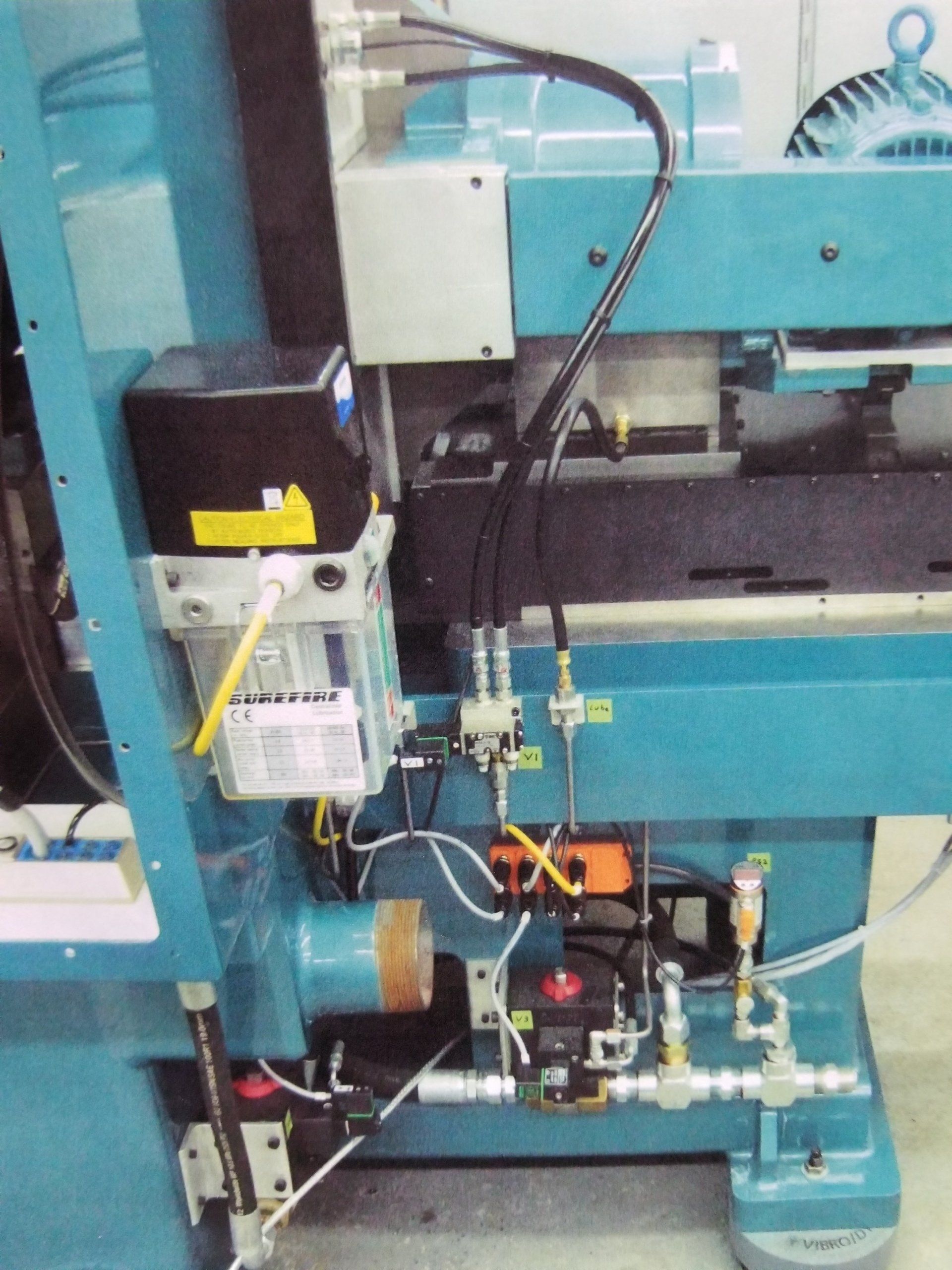

You might not think that the appearance of your industrial equipment makes a difference to their utility, but the look of your production area could be the factor that makes or breaks the awarding of a manufacturing contract. More than that, the right colors can help you warn for safety on moving parts, keep track of what is part of what production line, and more.

Beal & Company has the right tools and expertise to paint and refinish your industrial equipment and factory production areas. Call us today to treat your machine to our best!

Painting & Refinishing

Be confident in both the look and the function of your facility, so that you can keep your workers safe and offer potential clients tours with pride. Paint specific machines to keep your production lines separate, apply safety colors to moving parts for higher visibility, and more.

With decades of experience in custom automotive paint and prep work, Beal & Co. has the skills to paint just about anything you can bring us. Whether it's industrial equipment, your prized motorcycle, signage, a helmet, musical instrument, or a work of art, we can give it a custom paint job that absolutely glows. We use the same methods to properly prep your piece that we use for auto restoration: filling, smoothing, and cleaning the surface in order to get the best possible paint application, then priming, painting, and polishing to perfection. Once it's ready to go, the sky is the limit as to what we can paint onto it!

The Importance of Industrial Coating

Industrial tanks and other machinery without coatings are susceptible to corrosion and rust, which can cause hazardous materials to leak out if not properly taken care of.

Projects that deal with coating these large industrial storage tanks can be especially tricky, which is why it's important to go to a company with plenty of experience.

If you're looking at whether or not you need to get your tanks coated, keep reading to learn the importance of coating your industrial tanks.

Why Coat Your Industrial Machinery

Industrial coatings applies to the different types of coatings that can be used on industrial tanks, liquid storage tanks, and other industrial machines.

The application of these coatings gives industrial machinery a longer lifespan along with plenty of other benefits. There are many things you need to consider when deciding whether you need to coat your industrial machinery, such as what type you're going to use, and what benefits you are looking for.

Types of Coatings We Offer

Before we go into the overall benefits of industrial coatings, let us explain the different types we offer.

Direct-To-Metal Finishes (DTMs)

This coating offers superior anti-corrosive properties and is able to be applied directly to the metal without needing a primer.

This type of coating application is growing due to its efficiency and cost-saving benefits. DTMs are done by a brush or a spray application and are able to be applied to aluminum, steel, and other coated metals.

Epoxy

This non-toxic and chemical resistant paint is a popular choice for steel, metal, and even concrete. Epoxy is a thick coating and is used to help protect against abrasion, corrosive fluids, turbulence, and extreme temperatures. Once the epoxy cures it has a strength and resistance that is unmatched. It offers a sheen look and makes the surface easy to clean.

Urethane

This paint comes in a large variety of colors and has superior UV protection qualities and durability. Urethane coatings are typically used in original equipment manufacturer (OEM) products and have the ability to be customized for volatile organic compound (VOC) compliance.

VOC compliant coating is important because it means the system, substance, or application adheres to government regulations and isn't polluting our ozone.

Benefits of Industrial Coatings

Now that you understand the different types of coating solutions we offer, here's the benefit they add.

Prevent Corrosion

Corrosion typically happens when humidity is around 70% - 80%, and the air temperature is higher than 32 F. Depending on the climate, rust can occur on uncoated metal in as quickly as 4 to 5 days.

When you apply a coating to your tanks or other outside metals you're giving it an extra barrier to the outside world. This ensures your tanks are going to last outside for years rather than days. Epoxy and DTM coatings are the best options to prevent corrosion.

Durability/Abrasion Prevention

Industrial coatings offer outstanding durable and long-lasting results. Epoxy and Urethane are best to prevent abrasion.

Standards

Another reason you want to coat your industrial machinery is because of the higher performance standards it will have. You can preserve your investments, and avoid environmental damages.

Which Should I Use to Coat My Industrial Machines?

The best coating for your industrial machinery is going to vary depending on your specific environment and the machines purpose.

The best way to choose which application is going to be best for you would be to take a look at some of the other projects we've done that are similar to what your needs are.

Our team has over 30 years of experience in industrial painting and coating, so you can be sure that we have the right know-how and expertise to get your job done right the first time.

Why Choose Custom Coatings?

When we apply our industrial coatings, we use a primer coat, finishing coat, and follow all OSHA safety standards. These are three vital parts of tank and filter system coating that we're sure to always follow.

If you're ready for an industrial coating for your facility, be sure to contact Custom Coatings Inc. by calling 828-326-0953 today if you have any questions, or for a free quote.